Part 1: Challenging Glass: Clarity with Advantages

Part 1: Challenging Glass: Clarity with Advantages Acrylic’s most frequent comparison is with traditional glass. While both offer excellent clarity, acrylic boasts decisive benefits: **Weight** (Approximately 50% lighter), easing transport, handling, and structural support needs. **Impact Resistance** (Up to 17x greater), making it shatter-resistant and safer, especially in public spaces, vehicles, or homes with children. **Weathering Resistance** Superior UV stability prevents yellowing and embrittlement, outperforming many types of glass over time outdoors. **Thermal Insulation** Acrylic provides better insulation, reducing heat transfer. **Machinability** Easier to cut, drill, and shape cold. However, glass remains harder, offering superior **scratch resistance** and **heat tolerance** (acrylic softens around 160°C/320°F). For applications prioritizing safety, weight reduction, and outdoor durability, acrylic often wins.

Part 2: Facing Polycarbonate: Strength vs. Clarity & Cost

Polycarbonate (PC) is acrylic’s main plastic rival, famed for extreme impact strength (nearly bulletproof). PC excels in **security glazing**, riot shields, or extreme-duty applications. However, acrylic counters with key strengths: **Optical Clarity & UV Stability:** Acrylic is inherently clearer and far more resistant to yellowing from UV exposure long-term. **Surface Hardness:** Acrylic is significantly more scratch-resistant than softer PC. **Cost:** Acrylic is generally less expensive than PC. **Chemical Resistance:** Acrylic withstands many chemicals (like alcohols) better than PC, which can stress-crack. Acrylic is often the preferred choice where optical quality, scratch resistance, UV stability, and cost-effectiveness are paramount over ultimate impact strength.

Part 3: The Strategic Choice

Selecting between acrylic, glass, and polycarbonate hinges on prioritizing application requirements:

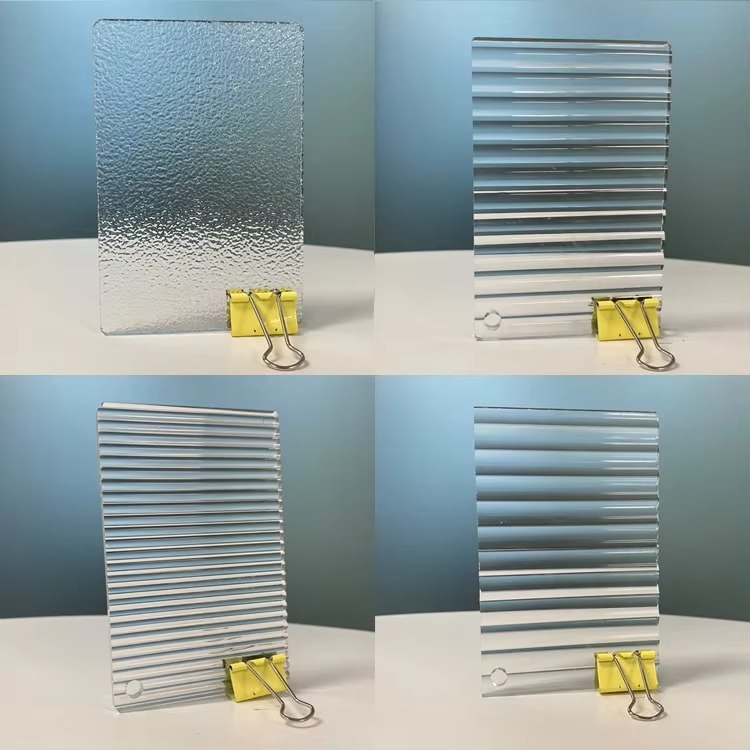

* **Choose Acrylic For:** Optimal clarity/light transmission, UV stability, scratch resistance, lighter weight, shatter-resistance (safety), good impact resistance, ease of fabrication, cost-effectiveness for high-clarity needs. (e.g., Displays, aquariums, signage, skylights, protective barriers, lenses).

* **Choose Glass For:** Maximum hardness/scratch resistance, highest heat tolerance, non-flammability, traditional feel (where weight isn't an issue). (e.g., High-traffic tabletops, oven doors, high-heat applications).

* **Choose Polycarbonate For:** Extreme impact resistance, bullet/security applications, very high heat deflection temperature. (e.g., Bullet-resistant windows, riot gear, safety goggles for extreme impact, aircraft windows).

**Summary:** Acrylic carves its niche against glass and polycarbonate through a strategic balance of properties. It surpasses glass in weight, impact resistance, safety, and UV stability while matching clarity. Against polycarbonate, it offers superior clarity, UV resistance, scratch resistance, and cost-effectiveness, conceding only in ultimate impact strength. The optimal material choice depends on prioritizing factors like clarity, weight, impact level, scratch resistance, UV exposure, heat, and budget, with acrylic excelling in numerous high-clarity, durable, and cost-sensitive applications.