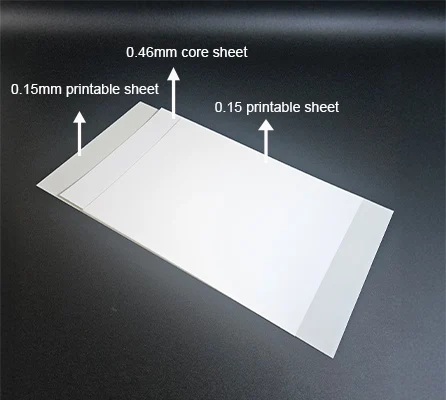

Prepare a set of non-laminating PVC sheets:

1 piece of 0.46mm core sheet

2 pieces of 0.15mm printable sheets

2 pieces of 0.15mm printable sheets

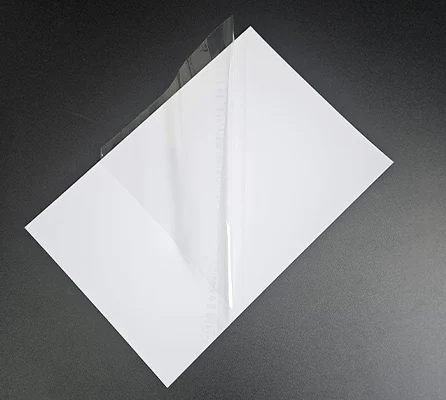

Non-Lamination dragon sheet

| Quantity (packs) | 1 - 1000 | 1001 - 10000 | > 10000 |

| Lead time (days) | 15 | 20 | To be negotiated |

|

Property

|

Standard Values

|

|

Thickness

|

0.76mm (0.15+0.46+0.15)

|

|

Size

|

200*300mm

|

|

Component

|

0.15mm transparent printable sheet

|

|

0.46mm whte core sheet

|

|

|

0.15mm transparent printable sheet

|

|

|

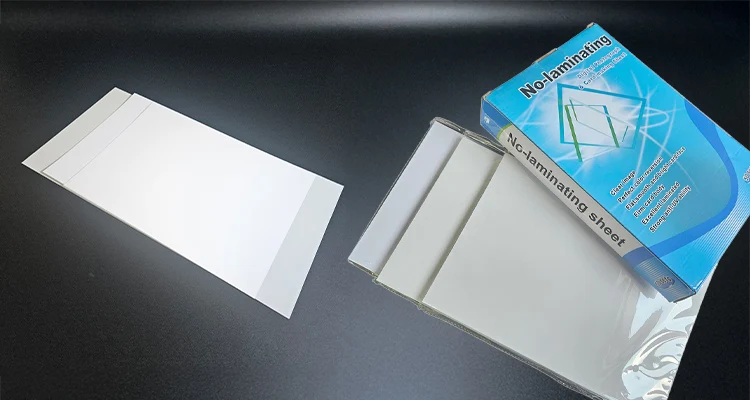

Packing

|

50sets/pack( 1 bag of core sheet, 2 bags of printable sheet)

|

|

Application

|

ID Card, employee badges, student IDs, membership cards

|