✅ Strong Bonding – Ensures excellent adhesion with PVC, PETG, or PC substrates during lamination.

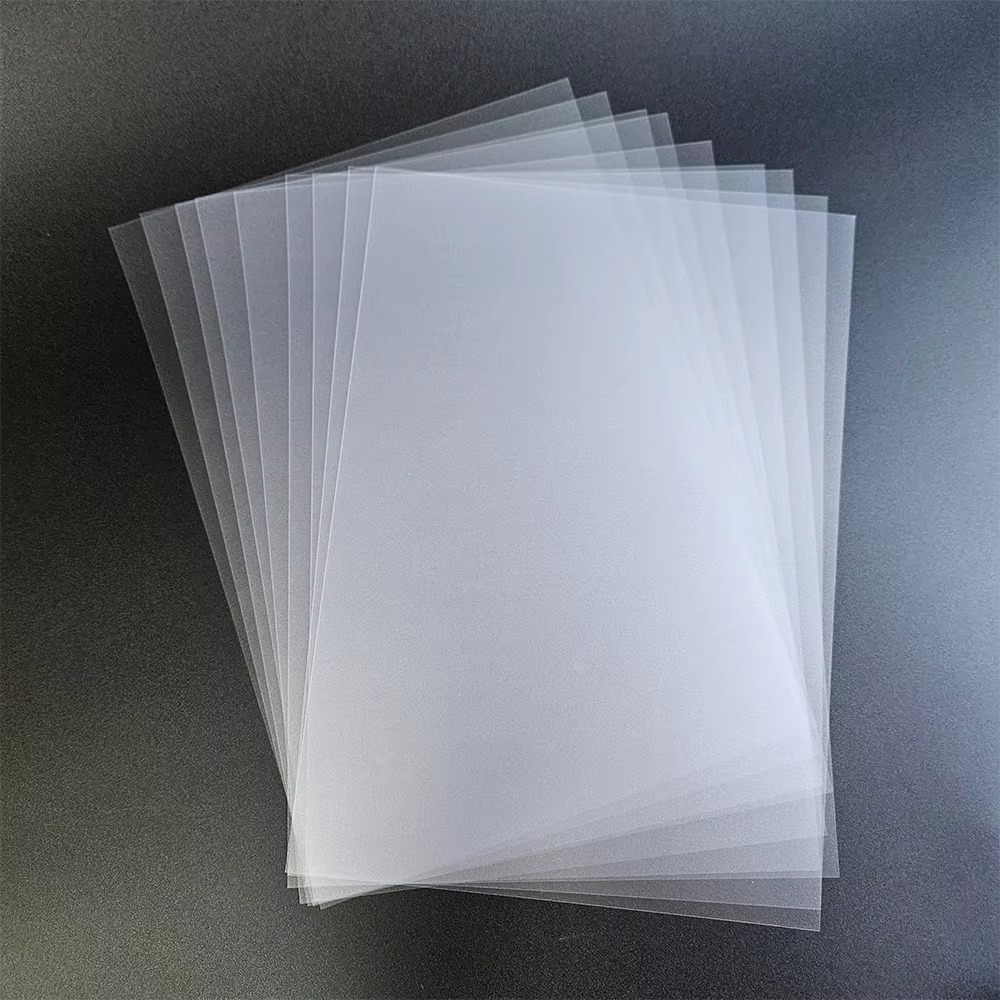

✅ High Transparency – Provides a clear, glossy surface for brilliant card appearance.

✅ Printable Surface – Compatible with offset, screen, inkjet, and digital printing methods.

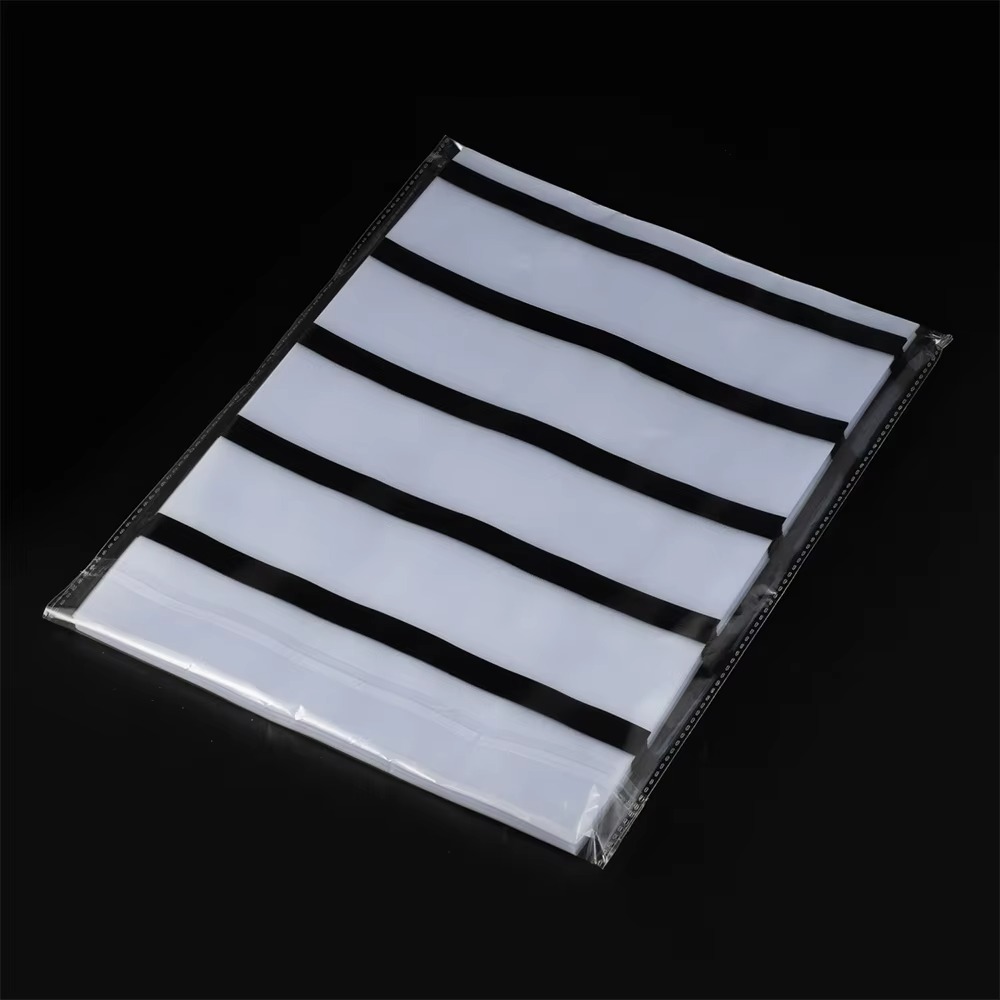

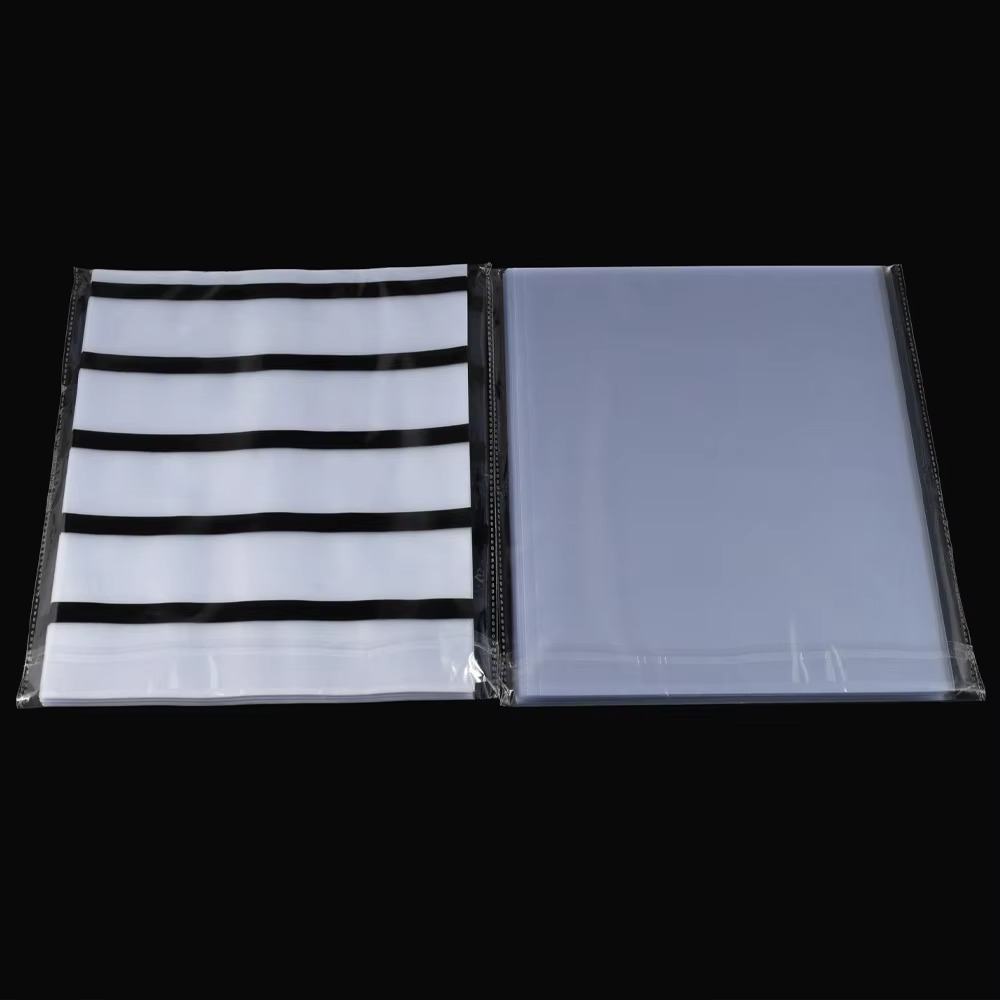

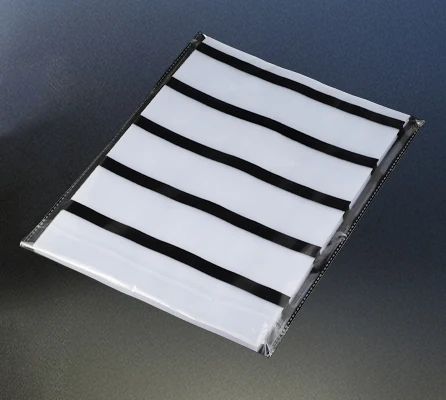

✅ Anti-Curling & Anti-Warping – Maintains flatness after lamination.

✅ Durable & Scratch Resistant – Improves card durability and wear resistance.

✅ Optional Coatings – Available in magnetic stripe overlay, inkjet coating, digital printing coating, laser hologram, etc.